Yeah the 2nd one is basically what I am trying to say in my broken english...

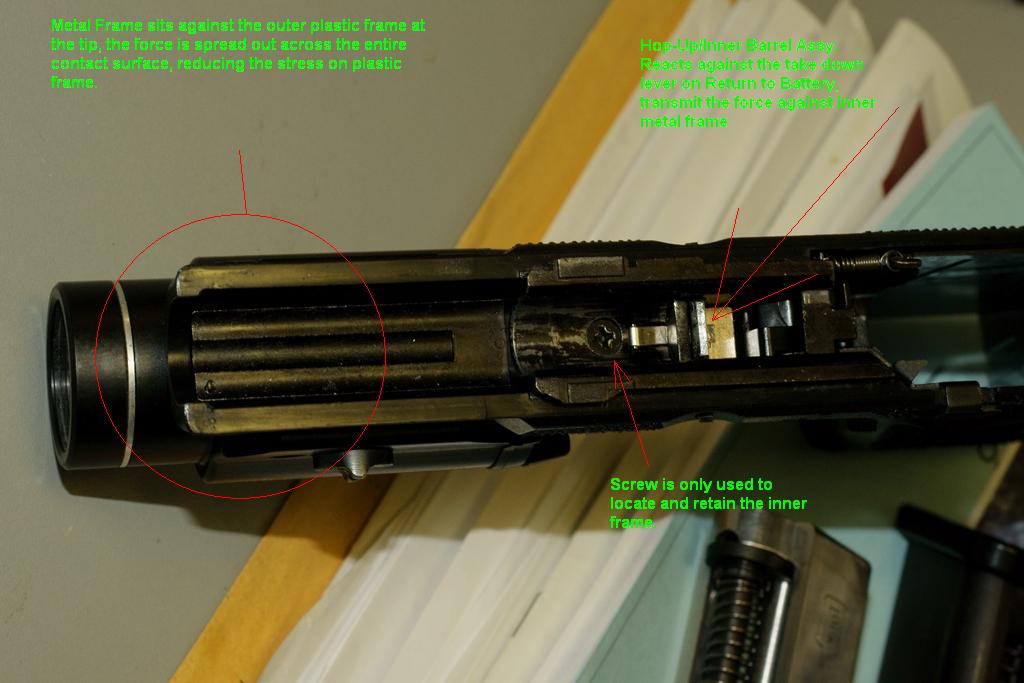

This is the stock TM frame on my Glock. If you take a look at a Guarder one if you get a chance you'll see the gap at the front of the metal inner frame is a lot bigger. And also the screw post on the frame is not as well supported. So all the cycling load on the returning stroke is taken up only by that screw post, and thats where mine snapped.

Edit, I noticed that the metal frame also sites against a feature on the plastic frame just in front of the "frame rail" portion of the metal frame. I need to look at the Guarder one when I get back to US but that gap might also be different from the TM frame...

In general I think its more of a reverse engineering tolerance issue, and perhaps not fully understand what some of the fit are for on Guarder's side in re-doing TM's frame...